Just after Christmas 2022 my original MiSTer stopped outputting HDMI. Initially I thought it was dead, however the VGA output was still working fine. I was a little bit sad as I had bought this DE10-nano on 21-Jul-2017, just a little time after the MiSTer project had started.

I pulled off the I/O board and had a look through my magnifying lamp. It was dirty but nothing major so I cleaned the HDMI connection and the board leading back to the HDMI chip using Isopropyl alcohol and a Q-tip. But this didn't fix anything the HDMI output was still dead. So I decided to pick up some replacement HDMI chips as I thought I had fried it with my new HDMI switcher.

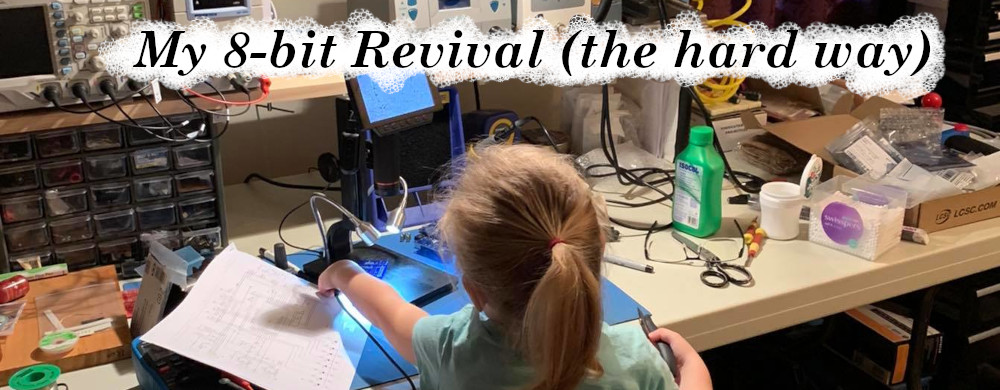

At this time my workbench was is complete disarray and I was planning to setup a proper bench as my old one was a rather warped plastic table. So I wasn't ready to do any fixing.

Fast forward 2 months and my new workbench is now all setup, ready for fixing.

. . . and so herein lies the lesson . . .

Once I got my microscope up and running I could see the corrosion and gunk still there right between all of the legs of the 65BRG IC right next to the HDMI port.

Proper cleaning on the DE10-nano can not be done with a Q-tip. You will either want to use a dental brush or an ultra sonic cleaner if you have one.

The problem I had was with one of the tiny IC's right next to the HDMI port. it seemed to have a build up of dust, flux and corrosion on it. After cleaning it you can clearly see the dis-coloured pins. The dental brush was the ideal tool ( with a liberal amount of Isopropyl alcohol ) to clean in between the legs.

Once the matter was cleaned away the HDMI port worked straight away.

After I clean you can see the legs on the IC on the right are no longer shiny.